ENERGY STORAGE AND ENERGY CONVERSION DEVICES

ENERGY STORAGE AND ENERGY CONVERSION DEVICES

Energy storage and conversion become increasingly important due to the increasing energy demand. With the increasing need for more efficient and less costly technologies for energy storage (batteries, supercapacitor) and energy conversion (solar cells, fuel cells), the new design and development of materials for cathode, anode and electrolyte play key roles for the sustainable development of the human society. Hence, our group have developed and improved the system and components in energy conversion and energy storage devices through past 13 years.

COMPUTATIONAL MATERIALS SCIENCE

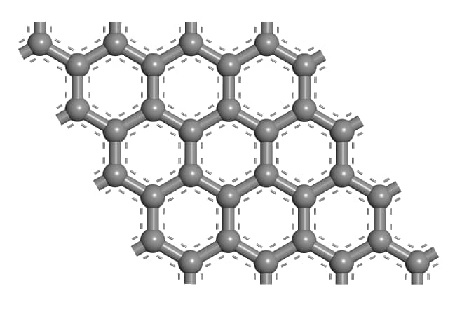

Technological advancement in this era is greatly rely on the development of advanced material and technologies will make the device to be smaller, portable and high performance are the main requirements of many users. These requirements motivated the materials scientist and engineer to produce new materials that will pushes further the capability of existing technologies. We use advanced computational methods to predict and calculate the property relationships for materials, enabling the identification and design of promising materials for new technologies. Materials hold the key too many advanced energy technologies including solar cells, batteries, fuel cells, sensors, piezoelectric and catalysis. With the increasing need for cost-efficient methods for energy storage and conversion, it has become imperative to accelerate the rate at which energy-related materials are developed. We use fast, scalable computational methods to identify and design new materials. Computational materials science is a relatively new discipline, and there is currently no consensus on a precise definition of what computational science actually is. In broad terms, computational science involves using computers to study scientific problems and complements the areas of theory and experimentation in traditional scientific investigation.

COATINGS AND MATERIAL SCIENCES

COATINGS AND MATERIAL SCIENCES

A new approach has been developed where by application of new technology or devising ways to add unusual properties to readily existing materials resulting in new products. This can be achieved through surface treatment or coating. Coatings, normally known as decorative and aesthetic functional besides having several purposes such as prevention of corrosion, slip resistance, impact and abrasion resistance, contamination resistance and hygienic properties resistance. Several interesting studies on thin-film approach coated on a series of metal substrate are conducted. Every advantages and limitations are depending on the selection of coating material, specified film properties and method of application of the coating. The use of natural resin as additional materials to produce new formulation of natural and synthetic binder are becoming more popular. With this area, our group actively studies on natural or bio-coating which can provide good performance and more environmentally.

ELECTROACTIVE MATERIAL

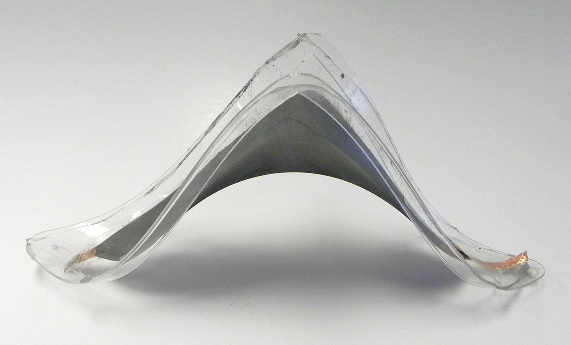

Electroactive material also known as electroactive polymer EAP’s are polymer that demonstrate change in size or shape when stimulated by an electric filed. The most common application of this martial is sensor and actuators. Ceramic piezoelectric material made up majority of actuator application. These materials are able to withstand larger force and commonly deform a fraction of a percent. Common application of EAPS is in robotics that develops artificial muscles thus this polymer often referred as artificial muscle. EAP can have several of type but generally divided in two groups

Dielectric - Dielectric elastomers are smart material systems that produce large strain. This actuation cause by electrostatic forces between two electrodes which squeeze the polymer. Dielectric elastomer is fundamentally capacitors that change its capacitance when a voltage is applied by allowing polymer to compress in and expand in are due to electric field. This type of EAP typically required a larger actuation voltage but low electrical power consumption.

Ionic - Ionic EAPs, in which actuation is caused by the displacement of ions inside the polymer. Only a few volts are needed for actuation, but the ionic flow implies a higher electrical power needed for actuation, and energy is needed to keep the actuator at a given position. Examples of ionic EAPS are conductive polymer, ionic polymer-metal composited (IPMCs), and responsive gels. Yet another example is a Bucky gel actuator, which is a polymer-supported layer of polyelectrolyte material consisting of an ionic liquid sandwiched between two electrode layers consisting of a gel loaf ionic liquid containing single-wall carbon nanotubes .The name comes from the similarity of the gel to the paper that can be made by filtering carbon nanotubes, the so-called bukypaper.